ART RESOURCES

Here you’ll find information on the best practices for producing the highest quality print in a timely manner.

ART RESOURCES

Here you’ll find information on the best practices for producing the highest quality print in a timely manner.

What is our printing process?

PRINTING METHODS EXPLAINED

Direct Print

- Various Clear Plastic PET and PLA Cups

- ECO-Friendly PLA Paper Hot Cups

- Paper Cold Cups

- Food Bowls

- 4 and 10oz Single Wall Paper Hot Cups

Full Color Print

- 8, 12, 16, & 20oz Single and Double Wall Paper Hot Cups

- Dimpled Coffee Sleeves

- Vinyl Stickers and Floor Graphics

- Paper Adhesives

- Various Clear Plastic PET and PLA Cups

Screen Print

- Apparel (T-Shirts, Outerwear, Polos, Aprons, & Masks

- Tote and Drawstring

Embroidery

- Hats

- Available on Polos (Contact a sales representative for embroidery pricing)

Some art may need to be adjusted when printing to meet production requirements, please review our tips for print or more information.

What is needed when submitting artwork?

TIPS FOR PRINT

File Formats

Vector artwork is recommended for the best quality print. This format allows us to scale the art to fit the product without any unintended loss of clarity or quality in the printing. To submit your art as a vector file please send file formats – .AI or .EPS.

Raster graphics such as .PSD, .JPG, and .PNG must be high resolution.

Acceptable File Types:

- .AI

- .EPS

- High Resolution (300dpi) .PDF, .PSD, .JPG, or .PNG

We do not accept files of the following types:

- Word/Pages

- Powerpoint

- Photographs or screenshots of logos or art

- URL Links

- Low resolution images*

*Additional charges may occur if a low resolution image is submitted in order to convert it to a printable file type.

Example of vector file

Example of a low resolution image

Fonts Within Vector File

Embedding Linked Files

- Select the layer with the linked file

- Go to Properties

- Choose Embed

- Save

If linked files within your art are not embedded this will result in a delay.

Resources for Designers

SET YOUR PRINT

UP FOR SUCCESS

Please try to prepare your artwork as close as possible to how you would like it printed. If adjustments are needed, please list them during the ordering process; the more we know about what you want, the smoother the process will go! Keep in mind that the longer it takes to get the art ready, the longer it will be before printing can begin.

Templates

Templates can be found on each product page. These templates are downloadable and can be opened in Illustrator. Please note these templates are to scale.

For best results, please reference our instructions on each template. It is important the print area, safety area, and bleed area be taken into account when designing. For best results please submit both your art files in their original high resolution format without crop marks as well as your template design. This allows the art team to make any necessary adjustments for bleed while staying as close to your requested design as possible.

Revised Print

Color for Printing

Color Conversion

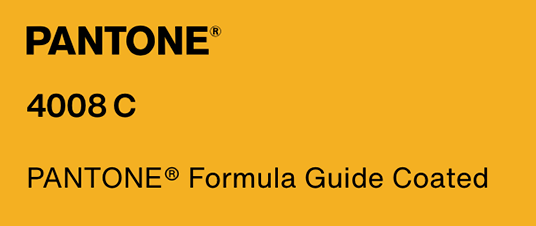

Example of how the same PANTONE color can look different depending on the printing method.

Please contact a sales representative at [email protected] for answers to print questions.